During the construction of metal based buildings, one of the most critical elements are the column, because it is on them all the external loads are transferred as a result of acting on the object. Even in the assembly of any of the metal structures, columns mouting is a prior operation following the foundation preparation. They are carefully aligned and installed and after all the other steel frame elements are fixed to them: longitudinal and transverse beams, floors, fachwerk racks, trussses and so on. For this reason, the production of metall columns is a particularly important task with high demands to the quality of welding and the verification of required technical conditions by the workers.

Design and calculation of columns

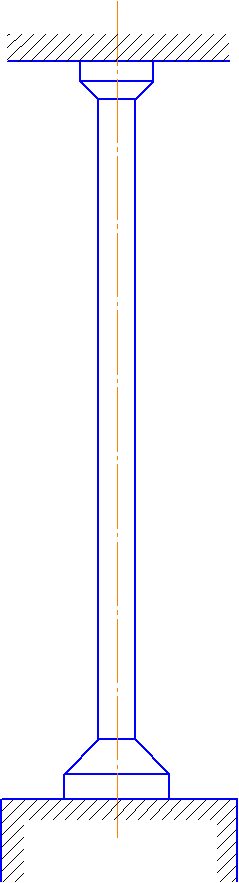

Any column, no matter how complex it looks at first glance, can be divided into 3 main elements: the well head, the stem and the base.

Head

The upper part of the column. Accepts external loads and transfers them on to the column rod and further to the foundation.

Rod

The middle part of the column, its working area. If necessary the rod can be reinforced with plates (at the connection with the base and the head part), and stiffness ribs.

Base

The place of fixing column to the foundation, which is made, usually, via the anchor bolts.

The column cross-section have practically any shape, but in most cases designers use:

- hot rolled I-beams,

- rectangular profiled pipe,

- round tube.

The resultant column cross-section size is chosen after the strength calculations. Columns operate in compression conditions, and this type of load is not extreme in terms of reaching the yield point and the subsequent nominal destruction. The stability loss is much more critical for the column, whose sensitivity to such crash event is determined not only by its design, but much the way the column interacts with the other elements of the building (if there is cross-linking or fachwerk racks etc).

Non-standard column support.

Column types

According to cross-section constructive, columns can be divided into several types:

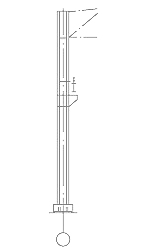

Constant cross-section column

The column consists of a single rod, a clearly marked crane console and a base. These columns are typically used in frameless buildings, hangars, warehouses. They allow for installation of transport and lifting equipment with carrying capacity up to 20 tons. They can be used both in single and multi-storey buildings. Sectional dimension of such a column is not varied along its length, but the cross-section area may vary in height in accordance with the calculated forces.

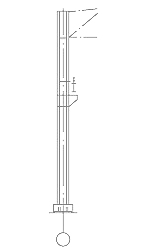

Stepped column

Used for the cases when a jib with lifting capacity of 20 tons and above will be installed at the building. This design increases the bending resistance of the column and substantially reduces the tendency to buckling. Stepped column consists of two branches: the main carrier, which serves as base for the roof trusses, and the runway, which is subjected to the loads directly coming from the crane equipment.

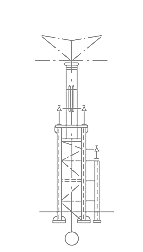

Separated column

These columns are not common and are used only in exceptional cases:

- with a low height positioning of highly loaded cranes;

- with multi-tiered arrangement of jibs;

- during the workshops reconstruction (for example, with increasing number of spans).

Columns can perceive loads in various ways in respect to their axes.

-

Axially compressed column

All the loads, resulting from beams, trusses, floors, etc, are strictly alinged with the column center line, that creates a central compression of the section. In the buildings with this type of columns loading, horizontal forces are transferred to additional crosslinking elements.

-

Eccentrically compressed columns

For such columns the resultant compressive force is applied at some distance of the central axis, which creates a bending moment. In addition longitudinal forces can act on the column. In such cases, the column may have an asymmetrical cross section for a more uniform distribution of internal, which saves material and reduce the weight of the structure.

Metal columns manufacturing at the SMS-M plant

In our practice we have had experience with all types of columns listed above, and not only in manufacturing but also in design. Our engineers always evaluate the quality of the received project, and therefore, if necessary, may give recommendations regarding the constructive elements of the columns. They take part in all manufacturing stages, controlling the process, because the column is a very important element of any metal made building. We guarantee high quality of our products, which has been confirmed many times by our customers after first successfull projects, contacting us again regarding both manufacturing and installation of metal columns.

Warehouse columns and beams.