The principle of the oxygen-fuel cutting technology is based on the use of two gases for the material separation. A special gas-heater, commonly propane or acetylene, is supplied into a nozzle. As soon as the material surface is heated to 1000-1200 °C, the pxygen flow is fed, that immediately ignited on contact with a hot surface and thereby cuts the workpiece. Further, the use of the heater is no longer required and the cutting process is supported solely by the continuously supplied oxygen. Iron oxides emerging during the cutting process are removed by the flame jet.

Oxygen is supplied under very high pressure - up to 12 atmospheres, so a particular responsibility is required to safety ruls.

Oxy-fuel cutting advantages

Such cutting type can be used in for cutting almost any type of steel with thickness from 1 mm to 300 mm. The main advantages of oxy-fuel cutting are:

- low cost;

- ability to work with thick materials;

- possibility to make both perpendicular and angled cuts.

Oxy-fuel cutting is normally chosen when the use of laser or plasma is inadmissible. We use it when we need to cut parts with thickness more than 30 mm. It is not surprising that the gas cutting is considerably inferior to more advanced modern technologies. There are dross problems here, cutting accuracy is a lot worse, kerf width is larger and thermal influence is quite significant. The latter issue is very important, since it may lead to warping, especially visible on thin sheets. That's why we usually use this cutting technology only for very large sheet metal thicknesses, when our plasma unit is no longer able to cope with the task.

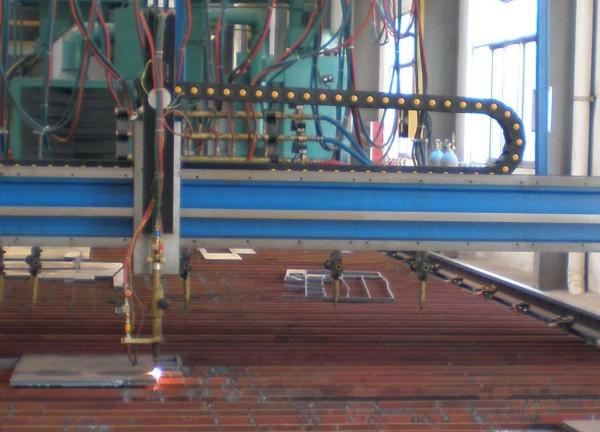

CNC oxy-fuel cutting

Initially developed for manual use, now the oxy-fuel cutting technology is effectively used in on CNC machines. So, our plasma cutting machine is additionally equipped with a gas cutting torch Harris, thus allowing to quickly switch from one way of cutting to the other depending on the sheet thickness.

Oxy-fuel cutting price

the rate in rubles per meter of cut

| Material thickness, mm | 10 | 12 | 14 | 16 | 20 | 25 | 30 | 40 | 50 |

| Price, rub. | 60 | 80 | 90 | 110 | 140 | 180 | 210 | 260 | 310 |

| Material thickness, mm | 60 | 70 | 80 | 90 | 100 | 120 | 150 | 200 |

| Price, rub. | 380 | 460 | 500 | 560 | 620 | 720 | 940 | 1350 |