Truss is a key element of any building made of steel, with no exceptions. Throughout its history, mankind has invented a great number of them, using a variety of materials and geometries. This type of construction has a high load capacity with relatively small dimensions. Since ancient times, it has been hardly possible to invent something simpler and more practical for the organization of the roof of any building or structure.

Trusses geometry

In today's engineering practice, the most common types of trusses are:

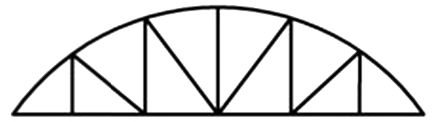

Arched girder.

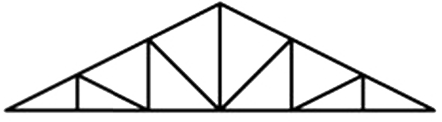

Triangular truss.

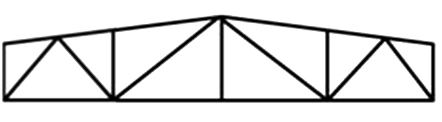

Trapezoidal truss.

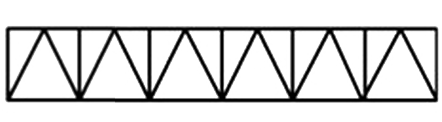

Truss with parallel segments.

The final choice of the geometry type depends on the roof configuration and required load-carrying capacity. The triangular and trapezoidal trusses are the most common. They provide excellent load carrying capacity, the optimum slope angle and relatively easy to manufacture. For large buildings these 2 types of trusses are also well connectable with each other.

From a technical point of view, the truss - it is a specially designed structure, whose elements exhibit only tension-compression forces.

In the case if a flat roof is required, trusses with parallel segments are appliyed. Usually this type of truss structures is used in construction of shopping centers, public buildings and warehouses.

Arched girder is the most difficult type, because its manufacturing process contains rolled elements, which of course affect the item price. The choice of such structures is generally justified by the aesthetic requirements .

Trusses manufacturing Features

In most cases, trusses are made of steel tubes of square or rectangular cross-sections or of an I-beam. These profiles are most practical ones, because they allows to design simple connections of trusses nodes with other elements of the roof.

Sometimes, doubled L-beams or C-beams are used to weld trusses. If doubled L-beams are chosenm they can be placed symmetrically (back to back) or skew (cross location).

Trusses elements, belts, braces and pillars are connected via metal plates, which are fixed with bolts or via welding.

Standard and non-standard trusses

When constructing a warehouse or any other industrial premises of large area, it is a common situation for us to deal with a series of typical trusses 1.263.2-4 vip.4. The series contains almost the completely finished documentation for the production of steel welded frames made of rectangular pipes or paired L-beams. The roof slope in the series is 3%, the span width is 15, 18, 21, 24, 27 or 30 m. These geometric characteristics are suitable for almost any hangar.

But even if a building has non-standard spans, the SMS-M engineers are ready to design your roof project in accordance with the customer's specifications and accounting for external loads and excitations.

SMS-M capabilities

Our steel structures workshop has high ceiling and include two 5-ton jibs and is suitable for manufacturing of very large frames of legth up to 12 meters and height up to 3 meters.